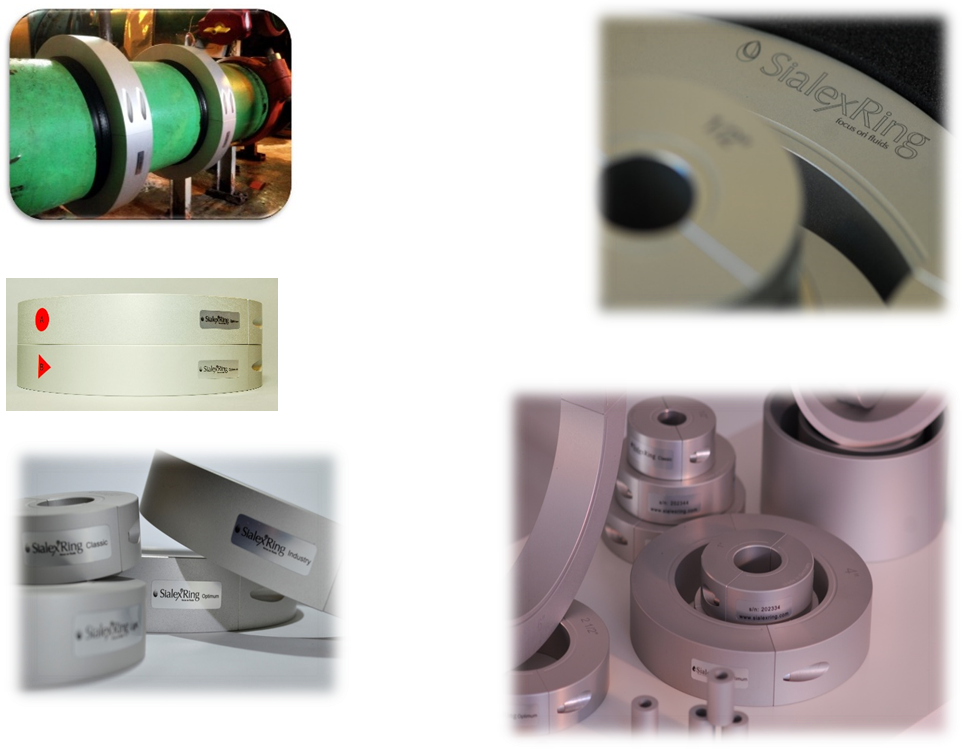

Sialex®Ring Industrial Type

These devices are employed in the control of “Scale” and “Corrosion” associated with water pipes and devices exposed to this water, as a result of these pipes carrying water.

Industrial Type Rings are mainly used in factories and industrial plants for a lower flow rate,

and ideal for water replenishment lines for boilers, replacement lines for the evaporative condenser, solar heater systems, among others.

Industrial Sialex® rings are installed in pairs, starting at 4 “

Flow rate: 4.0 m³/h (Size 1/2”) to 80 m³/h (Size 12”)

For bigger size Industrial rings, please contact us.

Sialex®Concept

Physics and Chemistry complement each other and help us understand the interaction of materials and the products / by-products produced as a result of these reactions.

Sialex® crosses the boundaries of physics and chemistry; Sialex®, devices employ physics based techniques both in their production as well as the “effects” achieved when employing such devices, to create what can be described as a “chemical” adjustment to materials present in fluids and exposed to the effects of these devices.

The Sialex®, products introduce additional “effects” on the movement of ions or charged “nano-particles” (colloidal) that are present in water. This effect results in a dissociation of the counter-ion charge cloud surrounding the ions or particles. This can allow a chemical reaction to occur that would not occur without the “Ring Effect” being present. It is the benefits of chemistry, without the addition of extra chemicals, which is of interest to Sialex®Ring customers.

Sialex®Process

The Sialex®Ring, installed around the exterior of the selected water bearing pipe, produces an increase in suspended “nano-particles” or “nucleation seeds” with a higher percentage of aragonite within the water exposed to the device.

Aragonite crystals form “soft” scale deposits that can be easily removed. The affect of the Sialex®Ring increases the number of nucleation seeds generated which in turn will cause more precipitation to take place in water than would otherwise occur. This results in more material moving through the water system than adhering to the sides of the water bearing pipes. These “seed” particles flocculate inside the water systems and form a fine “sludge” which can be easily flushed away as opposed to the more common “hard” scale deposits (calcite) which stick to inner pipe walls, is difficult to remove, and ultimately causes problems.

Another benefit of this technique, noted in residential properties, is less dissolved calcium bicarbonate in hot water circuits. This has the effect of improving lathering and providing other benefits of partially softened water… Easier to clean surfaces, less detergent, “softer” feeling water.