Sepiatec GmbH develops separation systems based on HPLC (High Performance Liquid Chromatography) and SFC (Supercritical Fluid Chromatography) technology, enabling our customers to speed up their separation and method development significantly.

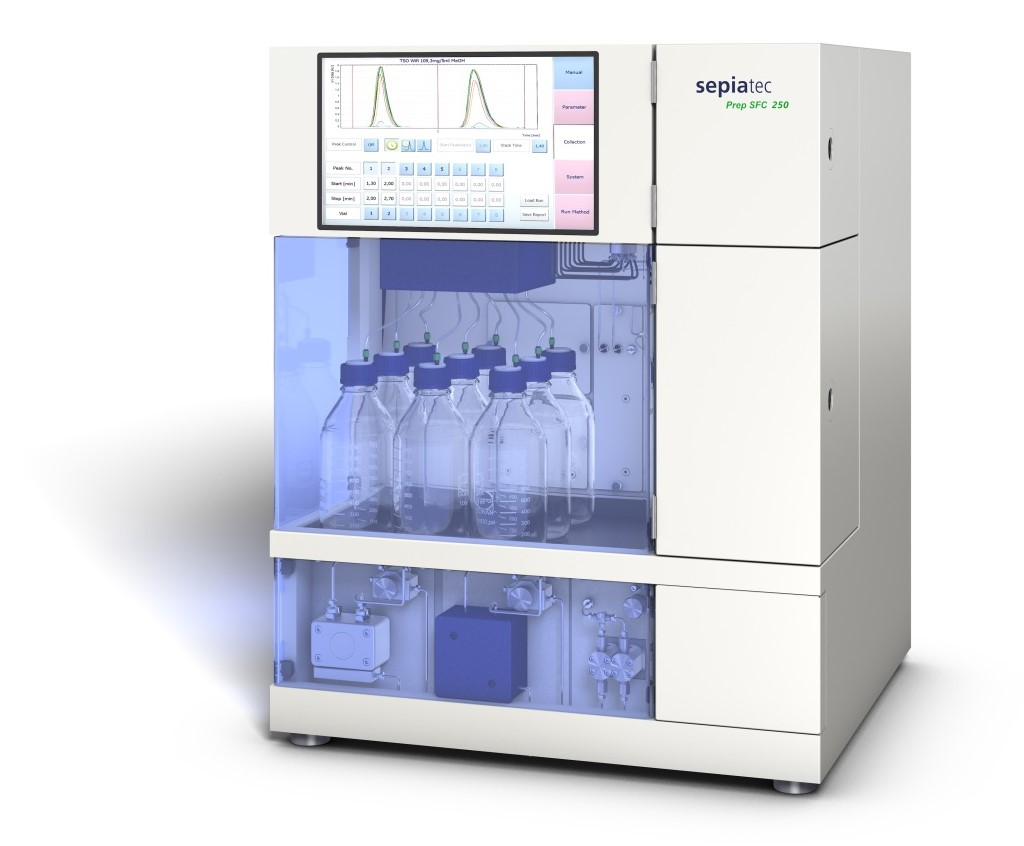

Sepiatec’s Prep SFC 250 system with 8 fractions and Max. flow rate 250 ml/ min at a modifier portion of 40% is a compact benchtop unit designed for preparative separations using supercritical fluid chromatography.

Measuring just 72 x 60 x 88 cm (W x D x H) the system offers all the advantages of SFC technology such as fast separations, reduced consumption of organic solvents, lower costs, improved environmental compatibility and increased safety.

The equipment of the Prep SFC 250 system includes:

– Designed for SFC separations on 15 to 30 mm ID columns

– 150 ml pumps for CO2 and organic modifiers

– Total flow rate of 250 ml/ min with 40% modifier

– Column oven for up to 6 columns

– Pressure-free collection, 8 fractions, unlimited volumes

– Easy to operate software, stack functions, on-the-fly editing

– Build-in system controller, no additional PC required

– Big 15.6” touch screen

– Connection: 3 USB ports, Ethernet, HDMI

Due to its compact design the footprint of the Prep SFC 250 system is comparatively small and precious laboratory space can be saved. The clear arranged assembly of the Prep SFC system allows easy access to all of its components.

Designed for 8 sample bottles

The fractionation module of the Prep SFC 250 system includes a selector valve and a gas / liquid separator. It is designed for 8 sample bottles with a volume of 1 liter each. Due to the flexible outlets even bigger sample containers with volumes up to several liters can be used.

The user-friendly control software can be used via the 15.6″ touch screen, which is placed ergonomically on the upper front of the Prep SFC 250 system.

A separate computer and a monitor are unnecessary, additional bench space is not required.

Optional equipment for the Prep SFC 250 system:

- Column selection valve for switching between 6 columns

- Add-on pump 30 ml pump head, for separations with low modifier portions

- CO2 recycling module for Prep SFC 250 system, For the conversion of gaseous to liquid

CO2, recovery rate about 85%

- External cooling device, Simultaneous connection to the pre-cooling and the CO2 pump

- Compact mass spectrometer, m/z 1200

- Compact mass spectrometer, m/z 2000

- DAD (Diode Array Detector)

- ELSD (Evaporative Light Scattering Detector)

Prep SFC 250 – Technical Specifications

| Operating mode | 1 semi-preparative or preparative column |

| Suitable columns | 15 to 30 mm ID, max. 250 mm in length |

| Solvents | CO2 and organic solvents |

| Number of modifier solvents | 1 standard, 4 with optional solvent selection valve |

| Total flow rate | 250 ml/min at a modifier portion of 40% |

| CO2 pump | 150 ml pump head, 400 bar |

| Modifier pump | 150 ml pump head, 400 bar |

| Add-on pump | 30 ml pump head, 400 bar (optional) |

| Operating pressure | Up to 300 bar, back pressure regulator online adjustable |

| Injection | Partial loop with syringe pump |

| Column oven | Ambient temperature to 70° C, 2 columns standard, 6

columns with optional valves |

| UV detector | Wavelength range 190 to 500 nm |

| Other detectors | DAD, ELSD or mass spectrometer optional |

| Number of fractions | 1 to 8 fractions, unlimited volumes, pressure free |

| CO2 Recycling | With additional CO2 recycling module (optional),

gaseous to liquid CO2 conversion, about 85% recovery |

| Software | Prep SFC Control software |

| System controller | Integrated controller |

| Screen | 15.6“ touch screen, 16:9 format |

| Connections | 3 USB ports, Ethernet, HDMI |

| Dimensions, weight | 72 x 60 x 88 cm (W x D x H), 135 kg |