Sepiatec GmbH develops separation systems based on HPLC (High Performance Liquid Chromatography) and SFC (Supercritical Fluid Chromatography) technology, enabling our customers to speed up their separation and method development significantly.

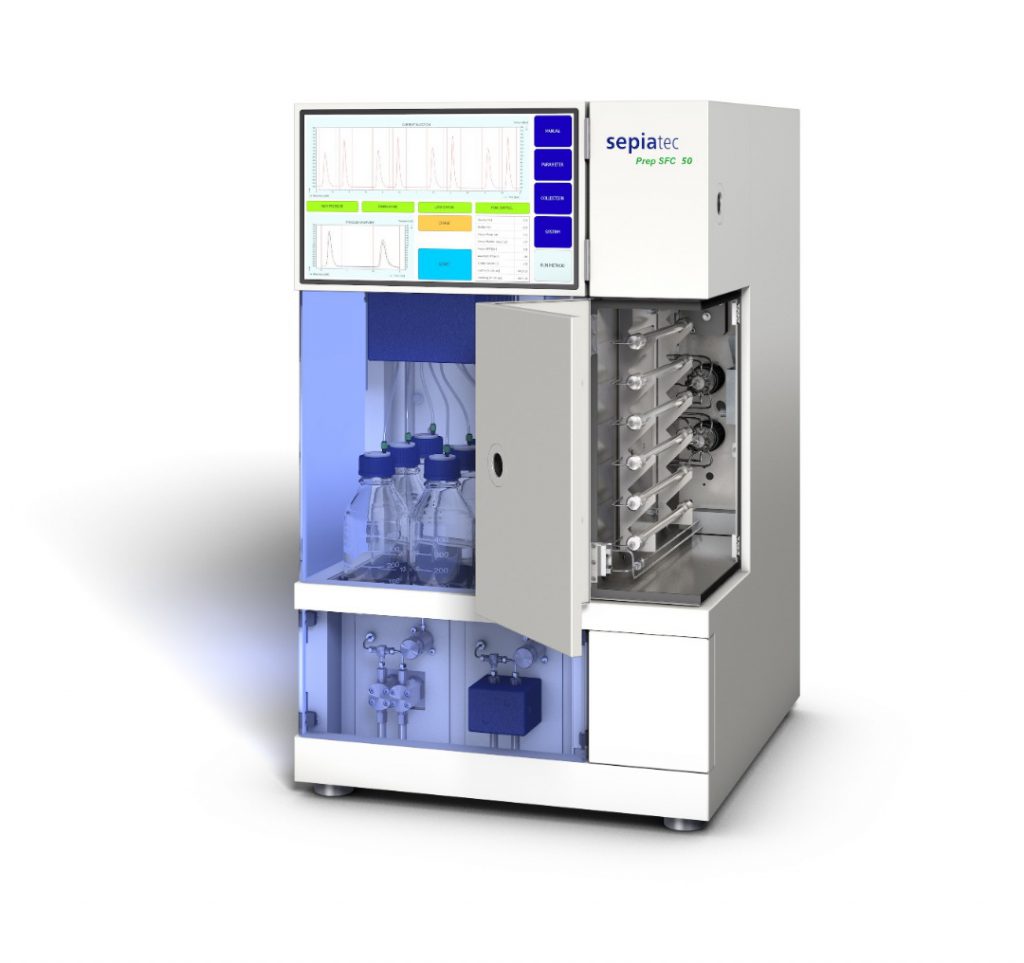

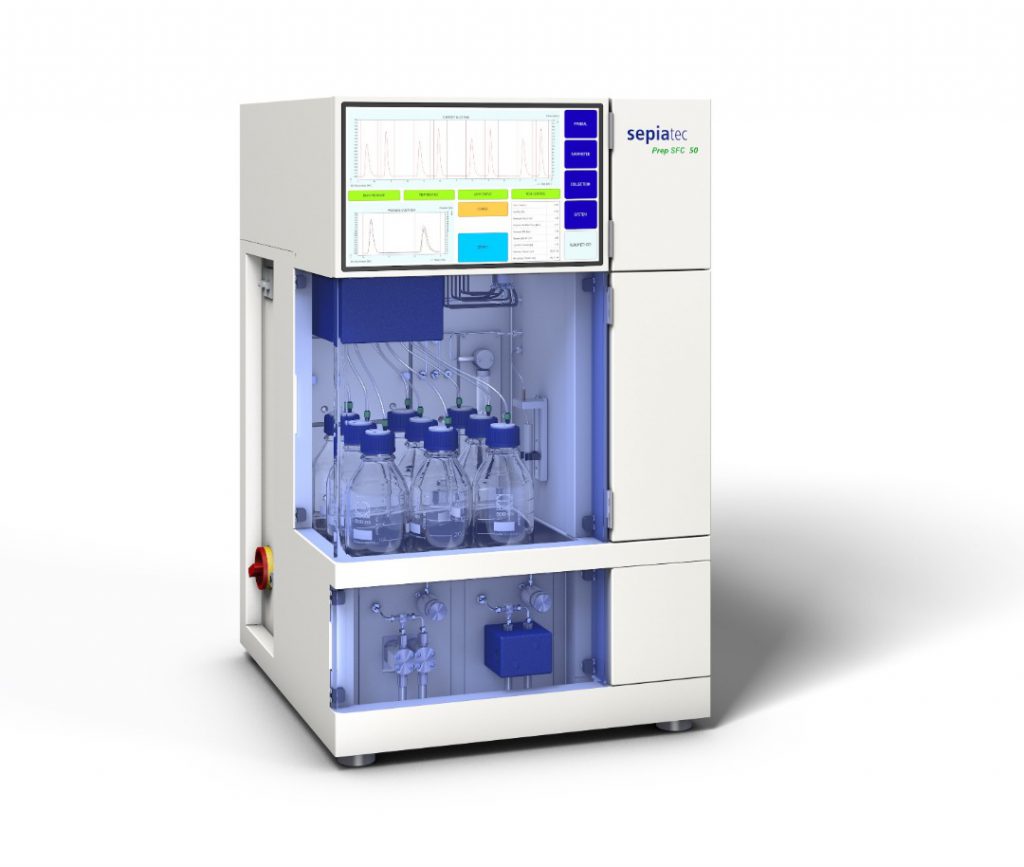

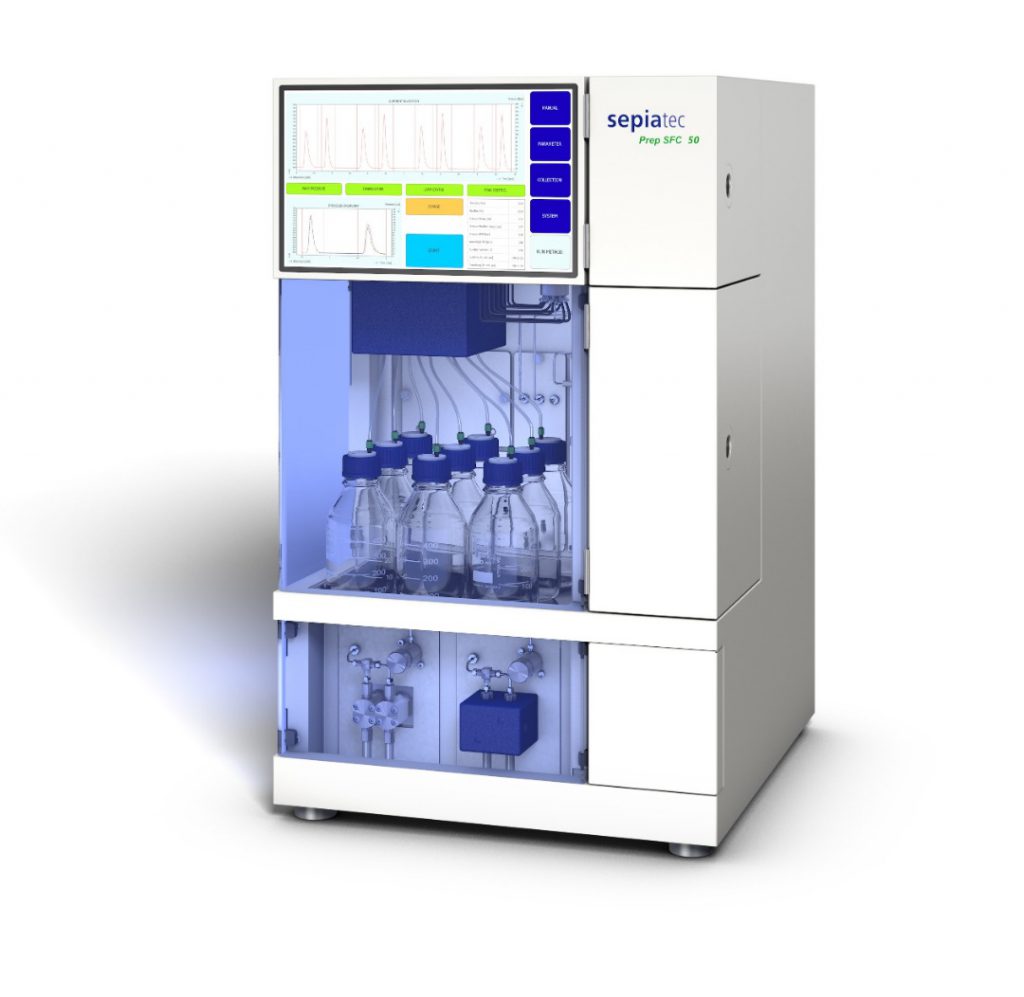

The new Prep SFC 50 new design Max. flow rate 50 ml/ min at a modifier portion of 40%, big column oven for up to 6 columns, 15.6” touch screen, all modules accessible from the front and service friendly, from Sepiatec is a compact and easy-to-use chromatography system for preparative separations on analytical and semi-preparative columns by means of supercritical fluid chromatography (SFC).

Faster separations

The system offers the comprehensive benefits of SFC technology, such as faster separations, lower costs due to reduced consumption of organic solvents, as well as being more environmentally friendly at increased safety.

Simplified Handling

As fractions are collected in unpressurized state, not only safety is increased, but also handling is simplified, and limitations with respect to the size of fraction volumes do not exist.

This option proves to be extremely convenient when working with stack injections.

As the dimensions of the Prep SFC 50 together with the integrated computer and touchscreen monitor this system requires a minimum of space in the laboratory.

A separate computer or monitor is not necessary.

The equipment of the Prep SFC 50 system includes:

- a high pressure pump for CO2

• a high pressure pump for organic modifiers

• a back-pressure regulator

• a syringe pump for sample injection

• a UV detector

• an integrated computer with 15.6 ‘‘ touch-screen

• 4 USB connectors (2 of them located at the front panel), Ethernet and HDMI-connector

• The Prep SFC control software

The Prep SFC 50 system is completely controlled by the Prep SFC control software, offering simple intuitive service due to a structured menu system.

All of the settings required for separations are available on screens.

The software contains functions like stack injection with automatic suggestion for stack time, and allows optimization of the fractionating parameters still in the course of the run.

Optional equipment for the Prep SFC 50 system:

- Column selection valve for switching between 2 or 6 columns

• Solvent selection valve for the modifier pump, max. 4 solvents

• Additional 3 gas liquid separators for collecting up to 8 fractions - Compact mass spectrometer, m/z 1200

- Compact mass spectrometer, m/z 2000

- External cooling device, Simultaneous connection to the pre-cooling and the CO2 pump

| Operating mode | 1 analytical or semi-preparative column |

| Suitable columns | 4 to 16 mm ID, max. 250 mm in length |

| Solvents | CO2 and organic solvents |

| Number of modifier solvents | 1 standard, max. 4 with optional solvent selection Valve |

| Total flow rate | 50 ml/min at a modifier portion of 40% |

| CO2 pump | 30 ml pump head, 400 bar |

| Modifier pump | 30 ml pump head, 400 bar |

| Add-on pump | 10 ml pump head, 400 bar (optional) |

| Operating pressure | Up to 300 bar, back pressure regulator online

adjustable |

| Injection | Partial loop with syringe pump |

| Column oven | Ambient temperature to 70° C, 2 columns standard, 6 columns with optional valves |

| UV detector | Wavelength range 190 to 500 nm |

| Other detectors | DAD, ELSD or mass spectrometer optional |

| Number of fractions | 1 to 8 fractions, unlimited volumes,

pressure free collection |

| Software | Prep SFC control software |

| System controller | Integrated controller, |

| Screen | 15.6” touch screen, 16:9 format |

| Connections | 3 USB ports, Ethernet, HDMI |

| Dimensions | 56 x 60 x 88 cm (W x D x H) |